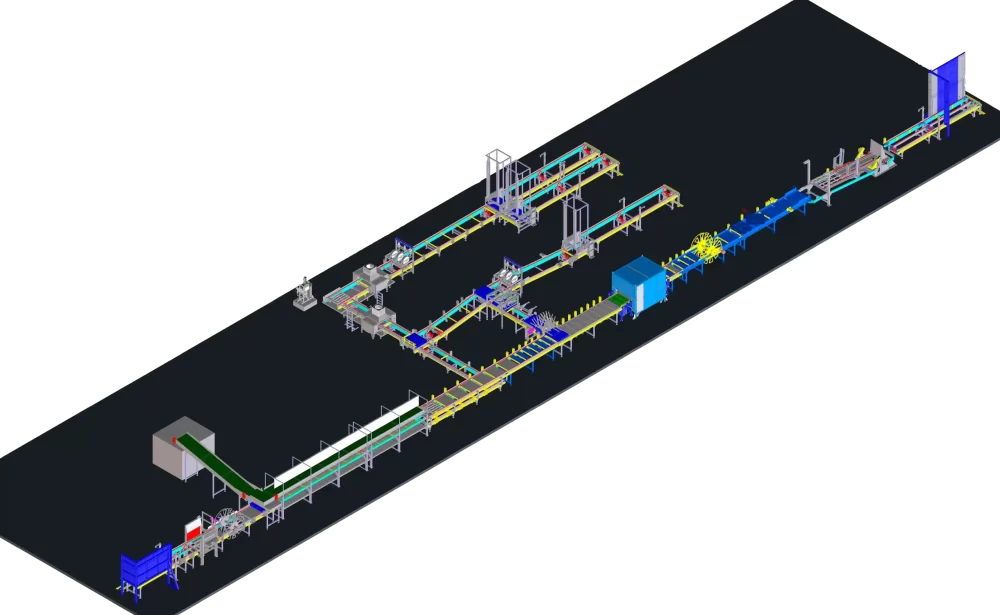

INFEED AND DESTACKING

- Reception of stacks containing several qualities of pallets.

- Front or side entry.

- Destacking of pallets.

Infeed machinery

Down Ender - Hydraulic destacker - 4 clamps destacker - Nested pallets destacker - Stacks turner

INSPECTION AND SORTING

- The sorting can be manual or automatic by means of pushbuttons, HMI or vision system.

Inspection and sorting machinery

6 or 10 blades noria (1 or 2 levels) - Vision system integration - Pop-up