Cattle and pig conveyors

iclomeat is the iclotet brand specialized in the automation of overhead transportation of pigs and cattle up to 250 kg. We offer solutions for the integral management of the logistic process:

Traceability – Product movement processes – Process automation – Logistics – Product management – Online maintenance

iclomeat is the iclotet brand specialized in the automation of overhead transportation of pigs and cattle up to 250 kg. We offer solutions for the integral management of the logistic process:

Traceability – Product movement processes – Process automation – Logistics – Product management – Online maintenance

PRODUCTS

rail type

PRODUCTS

rail type

Manual birail rail

Manual birail rail Tubular rail (manual or automatic)

Tubular rail (manual or automatic) PA semicircular profile rail (manual or automatic)

PA semicircular profile rail (manual or automatic) Manual birail rail

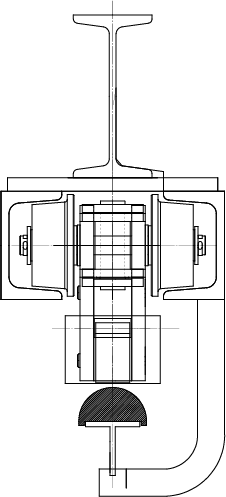

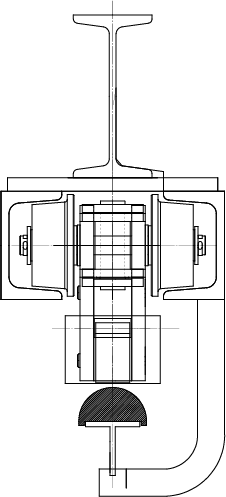

Manual birail railManual birrail rail

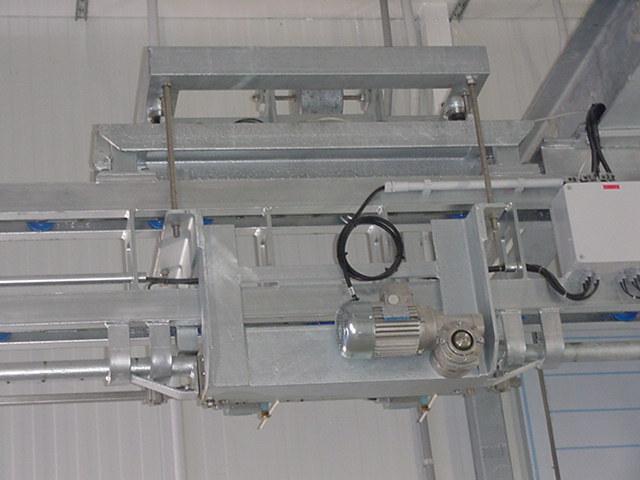

The birrail is a type of rail for meat transport. This type of rail is characterized by its inverted C-shaped construction and lateral guides, along which run the hooks with wheels, from which the carcasses or racks with pieces of meat are hung. The hook hangs from the central part of the rail, thus having a support wheel on each side.

The construction can be made of galvanized steel or stainless steel. Changes can be made manually or semi-automatically with pneumatic actuation.

It can be used for the transport or storage of carcasses.

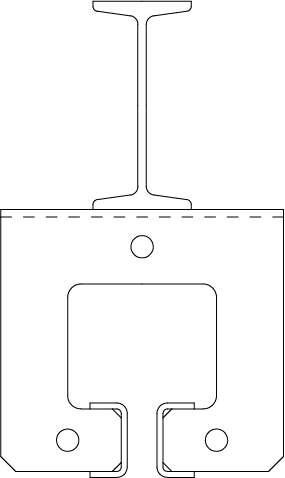

Tubular rail (manual or automatic)

Tubular rail (manual or automatic)Tubular in galvanized steel (manual or automatic)

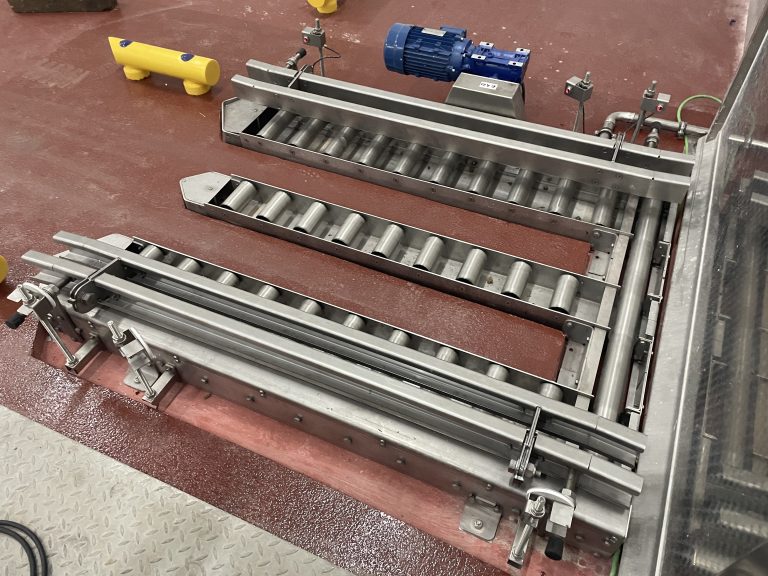

The tubular rail is a type of rail for the transport of meat hung on a European hook or with a sheave. As its name indicates, this type of rail has a tube as a support base; this can be of Ø48 or Ø60mm.

This type of rail can be provided for manual or automatic movement of the carcasses. If it is automatic, it will be a chain that will move the product along its path by means of triggers (or pushers).

It can be used for both transport and storage of carcasses.

The finish of the chassis and the support would be mainly of galvanized steel and the tube and its support, of stainless steel.

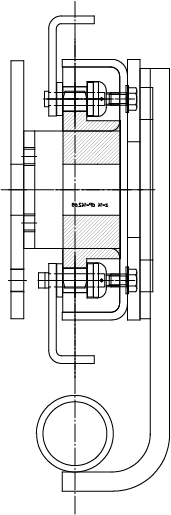

PA semicircular profile rail (manual or automatic)

PA semicircular profile rail (manual or automatic)PA semicircular profile rail (manual or automatic)

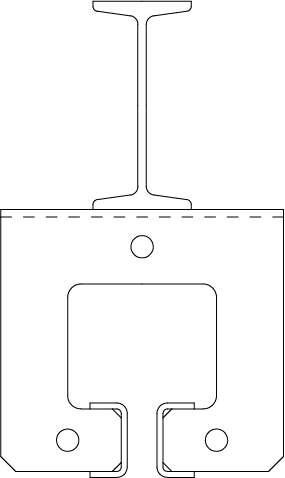

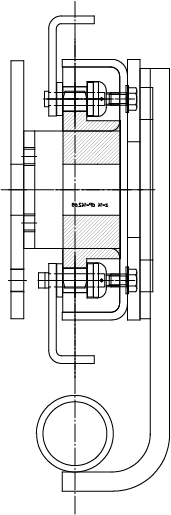

This solution is very similar to the tubular solution and replaces the pipe rail for a semi-circular polyamide profile, PA6, supported on top of a T-profile.

This material has a lower coefficient of friction and has the advantage that the passing of the product does not wear the structural tube, but the wear element can be replaced.

APPLICATIONS

pork- beef – hams

APPLICATIONS

pork- beef – hams

Rapid cooling chambers

We build rapid cooling chambers, which are used to cool the carcasses in a progressive way and for a certain time according to the client’s needs.

The transport will always be FIFO and will advance slowly in order to ensure that from the point of entry and exit of the tunnel, a certain time has passed and, therefore, the temperature of the carcasses has dropped as desired. Normally the total time will be between 1.5 and 2 hours.

Minimum temperatures can be as low as -30ºC.

Return of empty hooks

Nowadays, the return of empty hooks is a necessity in slaughterhouses, considering their volumes and production speeds.

We design and supply hook returns for European, roller or birrail hooks. The hook is brought from the cutting room, where it is released, to the beginning of the process where it is required. For a good optimization, an empty hook storage is included to be able to store them at the end of the shift.

This can include an automatic hook washing system and also a damaged hook detector (for hooks with sheave and birrail).

OTHER APPLICATIONS

OTHER APPLICATIONS

Design and supply of conveyor belts for all types of applications; cutting, picking and movement of boxes, etc. We manufacture all the necessary mechanisms during the product trajectory, such as diverters, weighers, gauges, etc. Machine automation and product traceability are included.

We install loading and unloading docks designed according to the customer's needs. We adapt the dimensions of the design in relation to the loading docks and the trucks that the customer has and are made to measure. They can be fixed and with manual position change or they can incorporate a pneumatic telescopic mechanism to facilitate the operation and the resting position when the dock is not in use. In principle, loading and unloading docks will be differentiated according to their slope (loading with a downward slope to the truck; unloading with a slope towards the inside of the building). However, they can also be completely flat, which would allow loading and unloading on the same dock.

The hydraulic arm allows an agile unloading, when there are no unloading bars available. It allows the load to be moved without difficulty and to be lifted to the desired rail height. The same hydraulic arm can be used for two docks if they are consecutive and we place it in the middle.

Hydraulic scissor lift with a maximum stroke of 2.200 mm and for a maximum load of 1.500kg. Possible application: jumbox filling, during which the lift will lower to allow filling. Once loading is complete it will fully raise to allow an operator to remove it with a pallet truck at ground level.

This application significantly improves operator ergonomics for palletizing boxes of product. The arrival of the product would be on one side of the elevator and the operator would start filling the pallet. Once a certain height has been exceeded, the pallet would be lowered to reduce the operator’s effort. Once the loading is finished, the pallet would be raised to ground level to be picked up by a pallet truck or electric forklift on the other side.

The unloading of hams arriving in umbrellas is carried out in an agile and semi-automatic way. With the help of 2 operators, one on each side of a conveyor belt, the umbrella of hams arrives and is then lowered with a descending conveyor. The evacuation of the hook is done without the operator having to touch the upper part of the hook and it is removed through the central part directly into a container. The operators help to unhook the hams and, by means of belts, the hams are directed to the high-speed ham classification area, which will divert hams by batches to the selected jumbox.

At the entrance to the pork butchering room, the pig must be laid down. For this purpose, an automatic chain descender is installed with a design that allows the correct horizontal positioning of the piece on a conveyor belt. The overhead descender and the horizontal belt must be synchronized to guarantee a good descent. In the middle of the process, the hook holding the part must also be automatically removed, and the part will be evacuated either to a container or to an automatic hook return conveyor.